“The JOB company has been committed to quality for over 50 years. Our numerous audits and certifications in recent years can confirm this.”

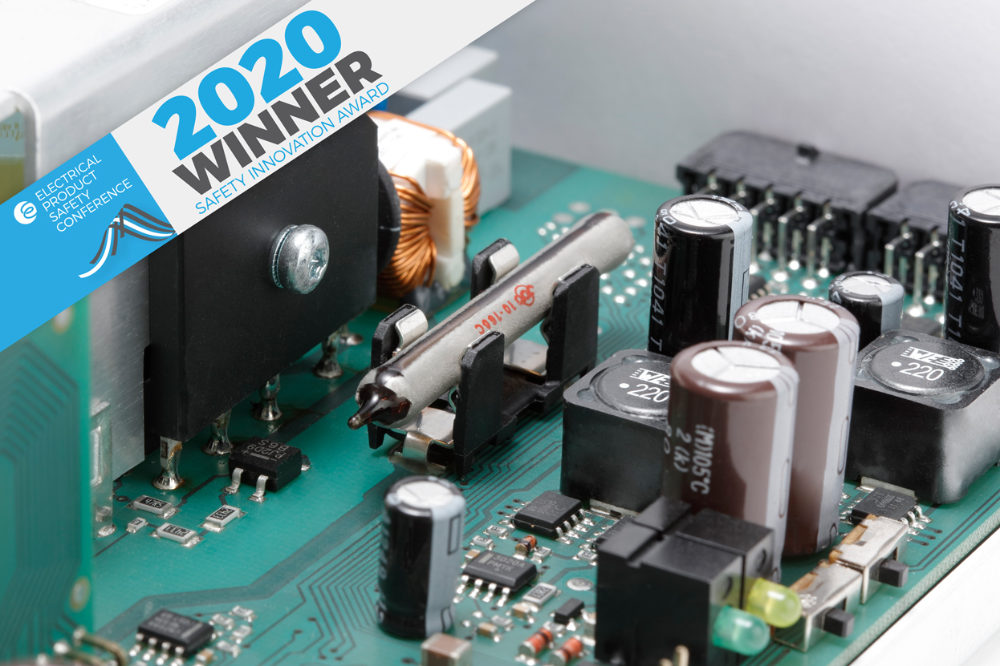

Fire-extinguishing thermal fuse

Mini fire extinguisher & smallest fire extinguisher in the world

The E-Bulb is a fire-extinguishing thermal fuse and consists of a coated glass ampoule filled with residue-free extinguishing agent. The smallest version is just two centimetres tall, as small as a typical micro-fuse, or a 1 Euro coin. This makes the E-Bulb the smallest fire extinguisher in the world.

If a fire starts inside the electrical device, the E-Bulb detects the fire and extinguishes it automatically. In addition, the current is permanently interrupted to prevent reignition. This prevents high consequential fire damage and reduces the risk of operational interruptions. Based on sprinkler glass technology that has been tried and tested billions of times, the E-Bulb was developed in Germany. 100% Made in Germany.

E-Bulb is an innovation that both protects and saves costs

An innovation that is worthwhile and saves lives. Find out 6 reasons why the E-Bulb will soon pay for itself. Simply click on the advantages and find out more.

Example:

Due to high fire risks, every major household appliance manufacturer has had to recall appliance lines in recent years. This can lead to a loss of image, which can be prevented so easily:

By using E-Bulbs, manufacturers implement preventive fire protection and product recall costs can be significantly reduced. Sometimes there is even no need to recall the entire range. A simple service case occurs for individual defective devices.

An example calculation for refrigerators:

Refrigerators sold per year in Germany: 3.6 million units (1)

Percentage of household appliances burning every year due to refrigerators: 8% (2)

Recall costs: €75 per unit

500,000 recall units x €75 recall costs = €37.5 million costs + significant loss of image

BOM through E-Bulb: +5€ per unit

Statistics: one recall per manufacturer every 10 years (3)

Quantity sold in 10 years e.g. 5 million units x 5€ compared E.g. 37.5 million euros recall costs = +12,5 million Euro

(1) Statista, (2) Which.co.uk (3) CPSC.gov & Rapex, EU

As a manufacturer or operator, you can use the E-Bulb to be an important step ahead of your competitors because:

Different fire protection concepts can be used when designing electronics. Our aim is to increase the safety of electrical devices. By using E-Bulbs, the overall product costs can be reduced, for example by reducing or replacing flame-retardant materials. These materials are also often criticised for being harmful to the environment.

Insurance companies accept and promote the operation of electrical devices with device-integrated fire protection (e.g. E-Bulb). The general conclusion of insurance is made easier by preventive fire protection. For many insurance providers, this protective measure is even relevant to premiums. For manufacturers, this topic specifically concerns product liability/recall cost insurance and for operators, fire/business interruption insurance. Please feel free to contact your insurance company.

Anyone who uses E-Bulbs can completely protect themselves against operational interruptions, or at least shorten the interruption time. Every third fire in industry causes material damage of over 500,000 Euros. It’s a sad fact that some affected companies will not recover. Only 23% of all companies affected by a fire fully resume business. On the other hand, over 40% of companies have to stop their business completely after a fire (see “Logistics today”).

Hospital: Once a week there is a fire in a hospital in Germany. The origin of these fires often lies in electrical devices. Medical technology devices with built-in E-Bulbs reduce the risk of fire and thus increase safety for patients and protect against loss of income due to operational interruptions.

Hotel: Suppose a fire breaks out in a hotel minibar. Without device-integrated fire protection, only the sprinkler system ensures that hotel operations can be maintained. The room is usually closed for a few days and cannot be rented out – loss of income. E-bulbs in the minibar would allow the refrigerator to be replaced quickly in the event of a fire. The guests don’t notice anything, and business continues. The combination of a sprinkler system and device-integrated fire protection therefore saves money from possible consequential damage.

Industry: The cost of business interruptions in industry quickly rise into the millions. Securing production-relevant systems by installing E-Bulbs in power supplies as secondary protection pays off and makes business sense.

At airports or train stations, at government authorities or clinics, in shopping centres or building entrances: digital media technology is increasingly used as a signpost, for information, advertising, or to ease waiting times with entertaining content. The added value of digital signage systems is obvious. The situation is less clear when it comes to fire protection requirements and the approval of media technology for installation in sensitive areas.

An independent working group (ARGE) under the auspices of VdS Schadenverhütung has created the VdS 6024 guideline to set uniform nationwide standards for the first time.

Digital media technology now regularly receives installation approval in escape and rescue routes, if they are tested according to VdS 6024 and equipped with integrated fire protection.

Electrical devices tested according to VdS 6024 have a clear market advantage – also thanks to E-Bulb.

Makes safe electrical devices even safer

Fire protection and digitalization in harmony

Where is the E-Bulb already state of the art? Discover some areas of application for the E-Bulb.

Wherever many people come together, fire protection plays an important role. This is particularly true for Frankfurt Airport, which is Germany’s largest and busiest airport with almost 200,000 passengers per day and over 81,000 employees.

The safety requirements for the technical infrastructure are correspondingly high.

The fact that the electronics company Samsung has now received approval for the placement of large LED media walls in the airport is also due to an invention by JOB GmbH. Fire protection experts classify LED media walls with integrated e-bulbs from “fire causers” to “fire participants”, which is why they are also used in sensitive infrastructure.

Statistically speaking, there is a fire in a hospital in Germany once a week (see bvfa statistics). These fires are often caused by electrical equipment. In recent years, the demand for ventilators has increased worldwide, mainly due to the coronavirus pandemic. Ventilators can also be made even safer so that, as in the case of St. Petersburg and Moscow in 2020, several patients do not tragically have to die as a result of electrical fires caused by ventilators.

Fire protection for media technology: device-integrated fire protection in the form of the E-Bulb can be installed in most medical devices at low cost. More and more medical technology companies are already opting for this, are you?

Refrigerators, dishwashers, televisions: most people have many electrical appliances at home. Now that most smart homes and electrical appliances are permanently on standby and therefore permanently energized, the risk of fire in the home has increased: Every electrical appliance that is switched on is a potential source of fire.

Fortunately, the vast majority of household electrical appliances are safe. At the same time, the reasons why a fire can occur are so varied that a fire risk can never be completely ruled out. If a household appliance has a mini fire extinguisher built in, many people can sleep better.

News:

Asian household appliance manufacturer WALTON relies on E-Bulb in its TV sets.

The following practical examples show how diverse the areas of application for e-bulbs are:

Power supply units & control units: The fire-extinguishing fuse E-Bulb is installed in power electronics devices as an additional protective measure. In the event of technical defects, it prevents consequential fire damage and thus minimizes cost-intensive downtime during operation.

Lighting: E-bulbs are used in industrial hall luminaires, for example, to minimize the inherent fire risk from LED modules, drivers and plug contacts as far as possible.

Solar systems: In solar systems, the integrated E-Bulb fire stop safely interrupts the voltage and prevents major fires on the carrier systems.

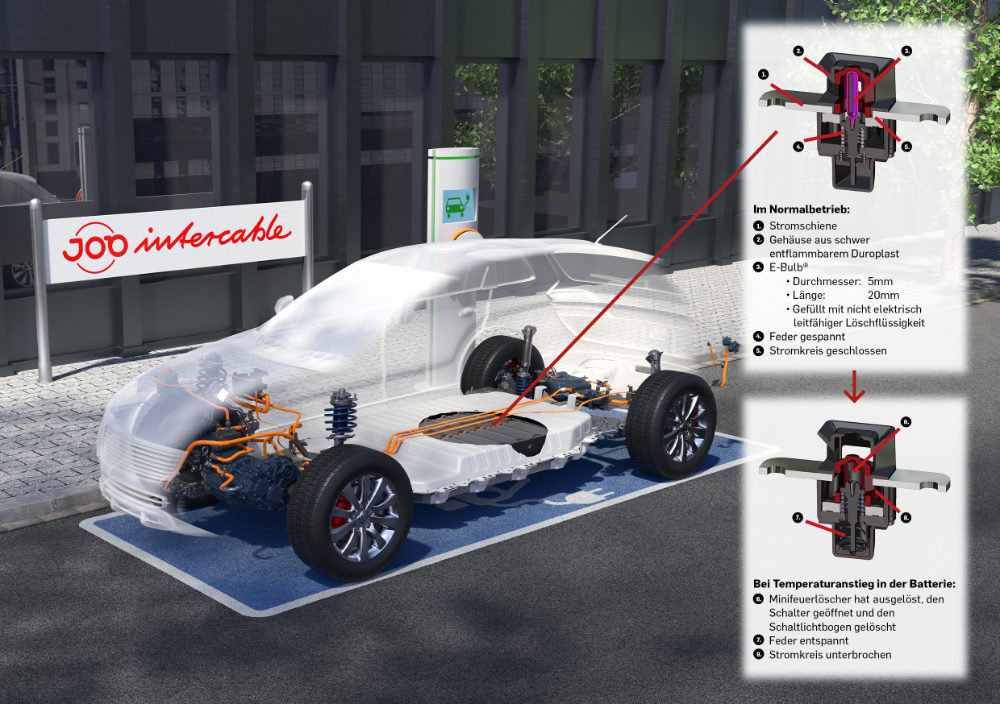

E-mobility demands new fire protection concepts. Together with the automotive supplier intercable, we have developed a Thermofuse (TP-Fuse).

The E-Bulb is installed in a flame-retardant housing. If the temperature rises above the temperature limit, it bursts and activates a mechanism that interrupts the current flow and thus reduces the voltage by switching off the battery segments. This greatly reduces the risk of short circuits and electric arcs or injury from electric shocks.

Learn more: https://www.job-group.com/wp-content/uploads/2024/11/TP-Fuse-intercable-Automative-Solutions.pdf

In our FAQ section we have summarised the most frequently asked questions and the corresponding answers.

Around one in three fires are caused by electricity, many in electrical appliances. Quality-conscious manufacturers have been bringing safe products onto the market for years. The causes that can lead to a technical defect and possibly fire are numerous and can never be 100% ruled out, even by manufacturers.

Common causes of fire are:

Statistically, there is a fire every 6 minutes in Germany due to electricity. Many fires start in electrical devices, including media technology. For example, in January 2021 a fire started from a presentation monitor in the world-famous motorcycle museum in Tyrol’s Ötztal. The entire museum was ultimately engulfed in flames and only a few of the valuable exhibits could be saved. This damage could have been prevented with device-integrated fire protection.

To avoid expensive damage or interruptions to operations in the event of a fire, it makes sense to detect the fire as early as possible, at the point of origin, and extinguish it directly while the fire is still small. It is precisely there, at the source of the fire, that device-integrated fire protection comes into play. The fire protection concepts that have been used in the past are good, but they usually only extinguish the fire once the fire has spread beyond the media technology.

Safe electronics can be made even safer with device-integrated fire protection.

The areas of application for E-Bulbs are numerous. They range from power adapters in advertising screens (media technology), to ventilators in medical technology, in household appliances in your own home, to battery systems in electric cars. The E-Bulb can be easily installed in the electronics and protects your electrical devices around the clock (24/7), even without power and in standby.

The E-Bulb is tested according to UL 60692. UL 60692 describes the requirements for Circuit Interrupters with Fire Extinguishing Agent for Use in Electrical Appliances and Components. Our E-Bulb meets all requirements of UL 60692.

Since the E-Bulb is a relatively new technology that combines the properties of different technologies:

an international descriptive standard is currently being worked on. The standard is developed in IEC SC 32c. A release is expected in the next few months.

“The JOB company has been committed to quality for over 50 years. Our numerous audits and certifications in recent years can confirm this.”

It helps us as a fire service enormously if electronic measures are taken to keep fires small or even extinguish them.

The integrated protection of electrical devices through device-integrated fire protection makes sense and can have a positive effect on the insurance premium.

Device-integrated fire protection allows us to install the digital house panel in house entrances and other sensitive areas.

As a distributor for components and a valued contact for electronics development, we particularly recommend integrated fire protection and the E-Bulb to our customers as “secondary protection”.

By using device-integrated fire protection in modern media technology from LED walls and digital signage to information points and product presentation applications, we, as an innovative system provider, have the opportunity to realise even more creative and flexible construction projects for our customers.

Step 1

Identification of hotspots

Step 2

Positioning of the E-Bulb in the design

Step 3

Confirmation of position through simulation & fire tests

Step 4

E-Bulb also protects the devices from the inside

Want support with installation into your electronics. Our JOB Design-in team is happy to support you

Note:

E- Bulb is a fire extinguishing thermal fuse (CIFEA; UL 60692) and a UL listed component.

Other sizes, other triggering temperatures, and uncoated versions (extinguishing function only) possible on request.

Information on “litres” and “ fl oz “: Designed according to NFPA 2001 “Clean Agent Extinguishing Systems”.

We protect larger volumes with the AMFE shown below.